How FRP and FRCM systems can be alternatives to traditional strengthening and repair methods.

The construction industry is constantly looking to innovate, research and improve its materials and technologies in pursuit of a sustainable future. Carbon fiber reinforced polymer (CFRP) is used primarily in the strengthening and rehabilitation of structures (Fig.1). This article highlights the use of fiber reinforced polymer (FRP) and fiber reinforced cementitious matrix (FRCM) in the repair of new construction projects.

Reasons for Repair in New Construction

Load rating upgrade

Several reasons that can cause the change in the loading system includes increasing live loads, installing new equipment, and change of use or building performance. For example, converting a building that was designed for residential load into a commercial space like a shopping center or parking garage is an example of change of use and increasing live loads. Also, changes to mechanical units installed in a building may apply new loads and can require repair or strengthening of the structure.

Damage

Damage that can make repair necessary include vehicle or crane impact, re, and blast. For example, trucks that transport materials like gravel, soil, concrete, etc. can impact the structure and cause damage to the new building. A miscalculation of the loads for selecting the proper crane for the project, or wind damage to the tower cranes, can cause serious damage to new construction projects. Fire can occur during welding or any torch applications. Blast damage could result from improper storage of chemical materials or terrorism attacks.

Environmental issues

Environmental issues such as rain, snow or temperature can affect the quality of concrete which may lead to a structural repair in a new construction project.

Design

If structural elements are undersized due to improper design, structural deficiencies like deflections can result during new construction or after completion when all loads are applied. These structural issues can lead to necessary repairs. Design changes during construction could also necessitate repairs or strengthening of the structure. For instance, changing the bathroom location can change the drain hole locations and making new holes in a concrete slab may cut the embedded reinforcement requiring slab strengthening to compensate for a reduction in structural capacity from the cut reinforcement.

Construction Issues

Poor construction can cover many items that a contractor can miss or perform improperly, including layout errors, inadequate forming and shoring, overloading the structure during construction, and low concrete strength. Missing or improper placement of rebars or PT cables in a concrete slab, poor quality concrete, and large width cracks are examples of poor construction (Fig.2).

Mistakes with structural members such as incorrect concrete column or beam dimensions/sizing or inadequate shoring to support the concrete slab or beam, could lead to excessive deflection that needs repair during the construction process. Storing construction materials on the structure may overload the structure and cause excessive deflection and damage. If the placed concrete strength is below the design strength, major collapse or partial structural failure can occur which makes a structural repair necessary.

Other issues could be from the excavation and foundation stage to final completion of the project. Construction errors in the foundation stage may indicate cracks or settlement during construction and after the building is complete. Poor welding in steel structures can require structural repair.

Fiber Reinforced Polymer (FRP)

FRP systems have been used to strengthen and retrofit concrete structure since the mid-1980s. FRP systems were developed as alternatives to traditional external reinforced concrete strengthening techniques, such as steel or concrete jacketing methods.

Fiber reinforced polymer (FRP) is a composite material consisting of fiber and polymer. The fiber is made of carbon, glass or Aramid, with carbon the most commonly used in structural retrofitting and strengthening. Fiber provides the strength and stiffness while the polymer acts as cohesive matrix to protect and hold the fibers together. FRP is used for reliable and high-performance structural strengthening systems. FRP systems are widely used for strengthening of dynamically and statically loaded buildings and other structures, providing long-term durability in service. FRP is manufactured as strips, bars and sheets to apply on concrete, steel and masonry surfaces.

The structural elements that FRP could be applied are columns, beams, slabs, walls, piles and pier caps (Fig.3). FRP is applicable to many types of structures such as tunnels, pipes and mines, tanks, silos, chimneys, parking garages, bridges, piers, wharfs and commercial and industrial buildings.

There are many advantages for using FRP systems as a structural repair or strengthening solution. FRP materials are lightweight materials and ideal for vertical and overhead applications. The repair and strengthening of structures are performed by using a thin layer of material. FRP systems have very low aesthetic impact and conform to existing shapes, have extremely high tensile strength, and has ease in installation. FRP features excellent chemical and corrosion resistance and the shipping of these materials is nonhazardous. Structural strengthening by FRP is a cost-effective solution and can be performed on concrete and steel structures. Prestressing of FRP is possible in the field if needed and is compatible with many finishes and protective coatings.

Like other materials, FRP systems have some disadvantages. FRP does not perform under elevated temperature. High temperatures can cause failure in the epoxy and the FRP matrix. FRP can be affected by ultra-violet (UV) radiation in areas exposed to sun such as bridge columns. The behavior of FRP systems under load is linear elastic to failure which means it does not indicate any sign like deflection before the failure occurs, and the failure mode is sudden without previous notice.

Fiber Reinforced Cementitious Matrix (FRCM)

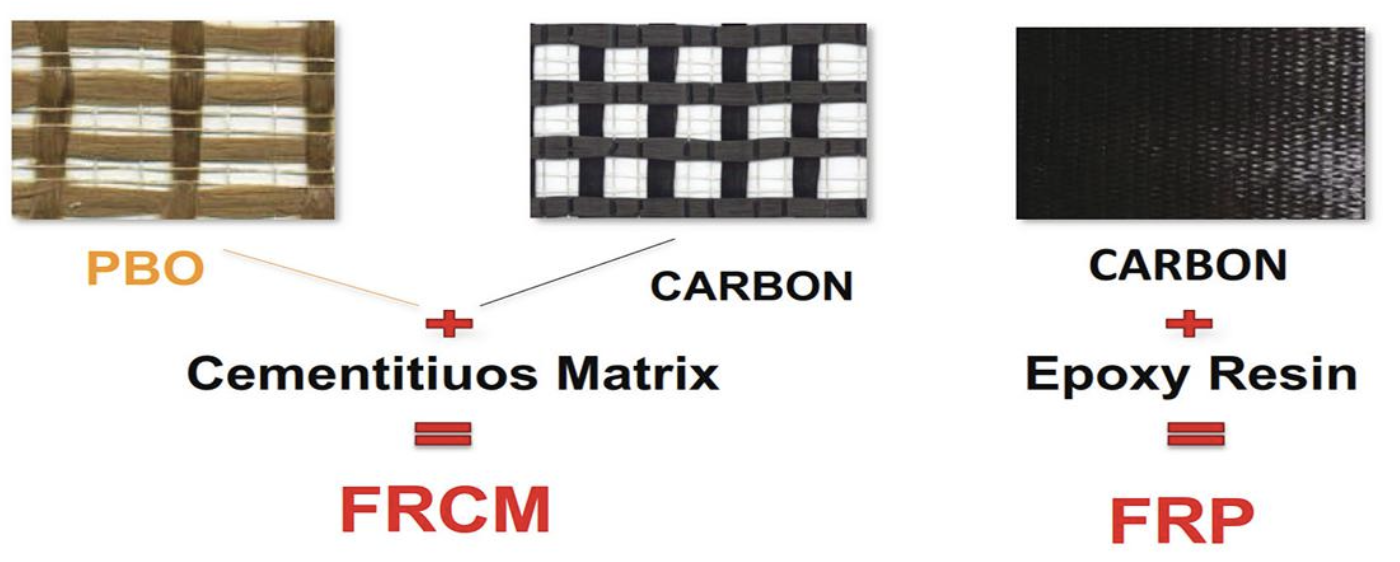

FRCM have been used in Europe the past decade and is now emerging in the United States. This system is like FRP, with the difference that FRCM is applied by cementitious material in lieu of polymer in the system (Fig. 4). FRCM wrap material could be Phenylene Benzobis Oxazole (PBO) or carbon (Fig. 5). FRCM can also incorporate a carbon grid in a shotcrete application which is thinner than the traditional shotcrete repair (Fig. 6). ACI 549.4R-13 is available as a guide for the design and construction of externally bonded fabric-reinforced cementitious matrix (FRCM) systems for repair and strengthening concrete and masonry structures.

Figure 5 FRCM – Phenylene Benzobis Oxazole (PBO) material.

FRCM composites have significantly different properties than FRP composites. Mineral mortar used as a matrix is not able to provide good coverage of all fibers versus epoxy resin and causes a slip phenomenon and telescopic effect, and a more ductile nature of the composite. e failure usually occurs as a result of debonding of the composite in the mortar-fiber layer.

Figure 6 Traditional shotcrete repair (left) vs. FRCM shotcrete repair (right).

Due to the nature of the work, the appropriate anchorage of the composite is an important element in strengthening with FRCM composites. Anchorage delays the debonding of the composite and increases load capacity of the element by engaging the mesh properties. e bond strength of FRCM to the substrate material is difficult to quantify as it depends on the type of fibers, fiber sizing, mesh layout, composition of the matrix, substrate properties, and quality of the surface preparation. Unlike FRP, the FRCM fibers are not impregnated; therefore, pulloff tests on concrete substrates typically show the failure within the fabric reinforcement or at the fabric-matrix interface.

FRCM has advantages compared to FRP systems. FRCM does not require a dry substrate and works well on damp substrates. FRCM has more resistance to re than FRP, as it is not affected by high service temperature. In most cases, FRCM does not require re protection. FRCM creates a breathable matrix and is not affected by UV rays.

Conclusion

FRP and FRCM systems are being used in the repair of structures in both new construction and existing structures as an effective strengthening technology. Due to their thickness, durability, performance, conformity to existing shapes, corrosion resistance, ease of installation etc, FRP and FRCM systems are great alternatives to traditional strengthening and repair methods and can provide an excellent solution for strengthening of concrete and masonry structures.

This article is a reprint of the article that ran in CRB Bulletin of ICRI in September 2020.

References

ACI Committee 549.4R-13, Guide to Design and Construction of Externally Bonded Fabric-Reinforced Cementitious Matrix (FRCM) Systems for Repair and Strengthening Concrete and Masonry Structures (ACI 549.4R-13), American Concrete Institute, Farmington Hills, MI, 2020.

Mantegazza, Giovanni, “Seismic Retrofit of Structural Elements with FRCM Prior to Recent Earthquakes in Italy”, International Concrete Repair Institute (ICRI) Spring Convention, Technical Presentation, April 2018.

Borwankar, Aniket, “Fabric-Reinforced Cementitious Matrix”, International Concrete Repair Institute (ICRI) Spring Convention, Technical Presentation, April 2018.