Why pull-off tests and tensile strengths do not allow statements about adhesive bonding efficiency.

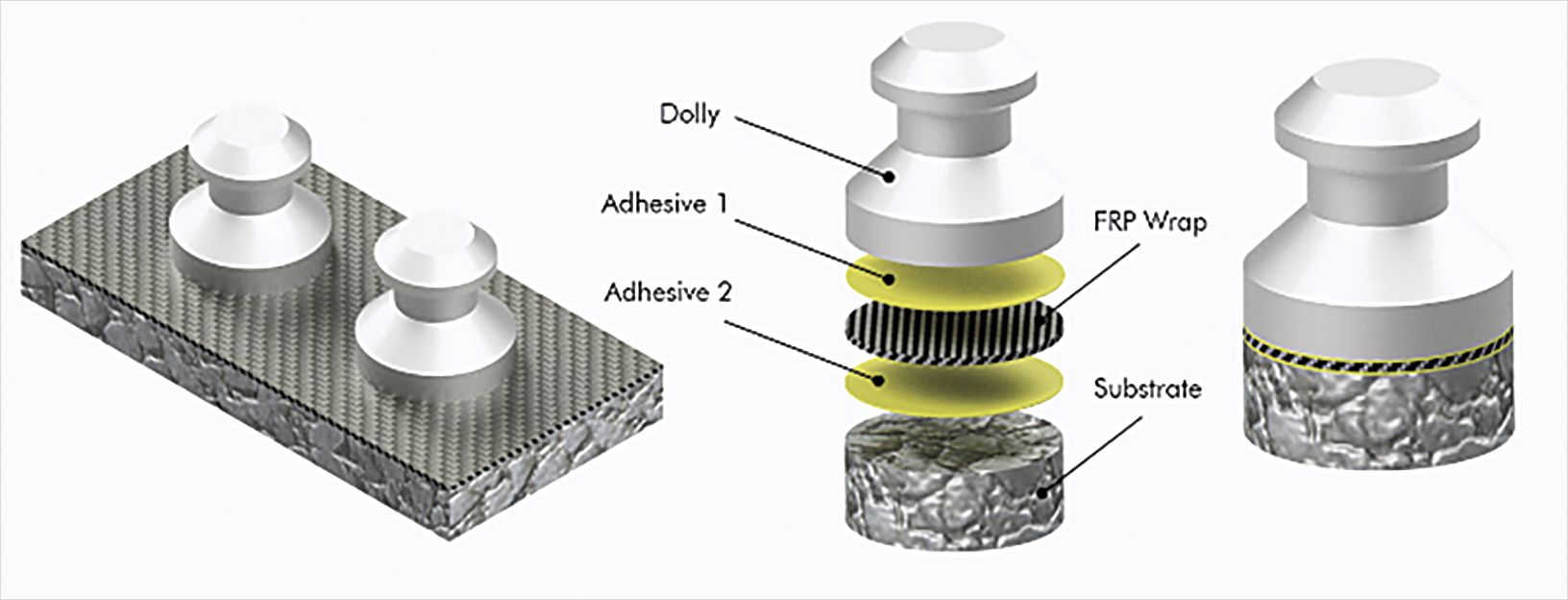

A literature review regarding concrete bonding reveals a limited number of publications specifically addressing bonding safety assessment. Some are dealing with pure concrete-to-concrete bonding, whereas others are focusing on the bonding of fiber composite components for structural external reinforcement of concrete buildings. Technically, this takes the form of wraps joined by epoxy resin bonding. Traditional mechanical test methods, such as the shear test and pull-off test, are used to characterize the adhesion properties of bonded concrete interfaces. As illustrated graphically in Figure 1, the latter is standardized by ASTM D7234 (Standard test method for pull-off adhesion strength of coatings on concrete using portable pull-off adhesion testers) and ASTM C1583 (Standard test method for tensile strength of concrete surfaces and the bond strength or tensile strength of the concrete repair and overlay materials by direct tension). There, a concrete slab is refurbished and adhesively bonded with carbon fiber reinforced plastic (CFRP) wraps. Adhesively bonded dollies are utilized to carry out pull-off adhesion tests by measuring the peak strength until the specimen ruptures. This simple and inexpensive procedure leads to quick results indicated by mechanical stress values. However, the main constraint is the complete omission of fracture-energetical parameters. Hence, a holistic multi-level principle is introduced to overcome such limitations.

In this context, the term “fracture analysis” means an evaluation of the structural safety of bonded concrete joints under pre-damage, also called “pre-cracking”. In doing so, a small initial crack is initiated in the interface and propagated in a controlled manner to measure softening parameters. It is a great advantage over the above-mentioned pull-off tests, which are technically and methodologically incapable of achieving this because of their technology and design.

Materials and Methods

Basic Considerations

Today, mechanical standard procedures are used to evaluate adhesively bonded concrete interfaces with tensile strength as a stress-based single-failure criterion. As indicated above, their major limitation is the ignoring of bonding quality, failure modes, and damage shielding effects from fracture analytics.

Reverse Failure Engineering

To overcome such limitations stated above, a three-stage evaluation principle called reverse failure engineering (RFE 3D) is introduced and applied on adhesively bonded concrete interfaces. It is composed of three different assessment dimensions:

- adhesion bonding quality,

- failure modes, and

- damage shielding.

Adhesion Bonding Quality

The first evaluation methodology is called the Adhesion Bonding Quality (ABQ). It describes the ex-post wetting of adhesive surfaces after the complete separation of bonded joint specimens by measuring the adhesive wetting in percent of the fractured surface. Already standardized, there are three classifications:

- poor quality,

- moderate quality, and,

- high quality (Figure 2, No. 1).

Failure Modes

The next dimension of evaluation concerns so-called Failure Modes (FM) of adhesive interfaces. They are classified into four types starting with cohesive, adhesive, mixed, and substrate failure (Figure 2, No. 2). The occurrence of one type of defect has a direct effect on the bonding reliability of the entire composite.

Damage Shielding Effects

These are phenomena responsible for crack propagation delay (Figure 2, No. 3). There are two basic types of Damage Shielding Effects (DSE): viscoelastic bridging (crazing) and mechanical interlocking. Fracture analysis determines the amount of energy an adhesive can absorb during cracking. This causes a crack delay or a stop of propagation. Basically, for an operator, the goal is to maximize and promote crack delaying properties.

Adhesive Bonding Efficiency

In contrast to mechanical pull-off test setups, RFE 3D stands out by describing failure processes in the interface by considering adhesion bonding quality, failure modes, and damage shielding together. All three assessment dimensions are combined into one key designation, the Adhesive Bonding Efficiency (ABE). This key figure allows one to evaluate and illustrate the performance of a bonded joint quickly and easily. Figure 2 describes this principle in detail.

The adhesive bonding efficiency is created by incorporating aspects 1, 2, and 3 (Figure 2) into a point-based rating system. Five evaluation levels according to the following grading key describe the possible state of assessment:

- Excellent (81% – 100%)

- Good (61%-80%)

- Average (41%-60)

- Weak (21-40%)

- Poor (0-20%)

Evaluation Procedure

Test Candidates

Table 1 shows a compilation of eight polymeric adhesive systems used for bonding concrete structures in a research study performed by Fracture Analytics. Specifications are taken from product sheets of the manufacturers.

11C stands for single-component. 2C stands for two-component. In the case of 2-component adhesives, both components are mixed in a mixing nozzle.

Test Setup

The setup is applied so that specimens are adhesively bonded to concrete plates and cured for seven days at room temperature. Testing is carried out in a laboratory on a universal testing machine. The fracture analytical events are accomplished in quasi-static loading for six samples per series. A structural safety factor SF and adhesive bonding efficiency are calculated by applying RFE 3D (Figure 2). The term “quasi-static” describes the dynamics of crack propagation. This means that static crack propagation is characterized by a very slow propagation speed. However, crack propagation is slightly dynamic, hence the term “quasi-static”. For evaluations, however, this is sufficiently accurate.

Results and Discussion

The results are illustrated in Figure 3 by showing a so-called peer-safety portfolio (PSP). It is designed to rate adhesives by the risk of unstable failure by plotting adhesive bonding efficiency (ABE) against adhesive bonding safety (SF). The results are depicted via traffic-light colored balloons of different sizes. Furthermore, the size of the balloon represents the damage tolerance, expressed by the GF-factor according to Hillerborg (Materials and Structures, 1985). The GF -factor is the specific fracture energy of an adhesive interface under loading released during crack propagation. It serves as an empirical and independent material property characterizing the crack growth resistance and damage tolerance.

Adhesive candidates can be categorized into high, medium, or low-risk entities based on the uncontrolled failure behavior of the cracking event. The findings indicate that strong and rigid adhesives, such as epoxy, polyurethane, and cyanoacrylate/acrylate hybrids perform poorly on bonding concrete. On the other hand, flexible and elastic adhesives reveal the opposite. Figure 3 shows that the green balloon associated with MS polymer (FAX) reflects a strong damage tolerance against unstable failure. MS polymer is an adhesive sealant hybrid between silicone and polyurethane – also called Silane Modified Polymer (SMP) or Silane Terminated Polymers (STP).

Hence, an excellent fail-safe behavior is observed. This is the case when strong and rigid adhesives fail to keep bonding performance at the interface. In case of overload, this means that a crack that spreads unprotected and migrates between the adhesive and the substrate results in uncontrolled debonding or delamination of the whole bulk. This has unforeseeable consequences and must therefore be avoided.

Alternatively, elastic-plastic adhesives can develop viscoelastic bridges (crazes) due to their chemical nature. Hence, crack delay can be achieved by increased energy absorption during crack propagation. From an operator’s point of view, this is highly desirable. In Figure 3, three clusters are marked up in red, yellow, and green balloons indicating different stages of adhesive bonding safety. Also, adhesion failure modes supporting this result are illustrated in the mid-section of Figure 3.

Conclusions

This research study applies a novel holistic evaluation procedure focused on different polymeric adhesive systems for rating concrete interface fractures analytically. Its core part is based on energetic fracture analysis combined with a three-stage evaluation procedure. These insights enable the following statements:

Pull-off tests are not designed for the characterization of interface failure effects of adhesively bonded concrete.

Tensile strength (stress) is not an appropriate evaluation parameter for assessing concrete interface safety due to the omission of energetic failure indicators.

High strength and rigid structural adhesives do not perform safely on concrete interfaces, as they generate new cracks in the concrete structure when subjected to recurring loads (crack shifting).

Elastic-plastic adhesives can generate safe bonds on concrete interfaces by developing damage shielding effects. This enables high crack damping.

A holistic evaluation principle called Reverse Failure Engineering 3D empirically rates adhesive bonding efficiency by generating safety indicators for a risk-adjusted selection.

References

M.E. Mohamad, I.S. Ibrahim, Interface shear strength of concrete-to-concrete bond with and without projecting steel reinforcement, Jurnal Teknologi 75 (1) (2015) 169-172, DOI: 10.11113/jtv75.3707.

P.M.D. Santos, E.N.B.S. Júlio, V.D. Silva, Correlation between concrete-to-concrete bond strength and the roughness of the substrate surface, Construction and Building Materials 21(8) (2007) 1688–1695, DOI: 10.1016/j.conbuildmat.2006.05.044.

B. Kabiri Far, C. Zanotti, Concrete–to-concrete bond in mode-I: A study on the synergistic effect of surface roughness and fiber reinforcement, Applied Sciences 9 (12) (2019) 2556, DOI: 10.3390/app9122556.

A.O. Hilal, A.Z. Hamoody, A.S. Saadoon, Behavior of FRP sheet-concrete bond in high strength concrete samples, IOP Conference Series: Materials Science and Engineering, 1090 (1) (2021), 012105, DOI:10.1088/1757-899X/1090/1/012105.

M.W.C. Himasha, J.C.P.H. Gamage, G.I.P. De Silva, V. Attanayaka, Modification of engineered cementitious composite mortar to use as an adhesive for CFRP/Concrete bond, ICSBE 2020, Singapore, (2020) 461-476, DOI: 10.1007/978-981-16-4412-2_35.

E.N.B.S. Júlio, F.A.B. Branco, V.D. Silva, Concrete-to-concrete bond strength: influence of an epoxy-based bonding agent on a roughened substrate surface, Magazine of Concrete Research, 57 (8) (2005) 463-468, DOI: 10.1680/macr.2005.57.8.463.

D.J. Cleland, A.E. Long, The pull-off test for concrete patch repairs, Proceedings of the Institution of Civil Engineers, Structures & Buildings, 122 (4) (1997), 451–460, DOI: 10.1680/istbu.1997.29833.

E. Bonaldo, J.O. Barros, P.B. Lourenço, Bond characterization between concrete substrate and repairing SFRC using pull-off testing, International Journal of Adhesion and Adhesives, 25 (6) (2005) 463-474, DOI: 10.1016/j.ijadhadh.2005.01.002.

ASTM D7234, Standard test method for pull-off adhesion strength of coatings on concrete using portable pull-off adhesion testers, 2021, DOI: 10.1520/D7234-21.

ASTM C1583, Standard test method for tensile strength of concrete surfaces and the bond strength or tensile strength of concrete repair and overlay materials by direct tension (pull-off method), 2010, DOI: 10.1520/C1583-04.

DIN EN 10365, Adhesives – Designation of main failure patterns, Beuth, Berlin, Germany, 2020, DOI: 10.31030/3156634.

DVS 3302, Bonding in car body construction: evaluation of failure patterns, Beuth, Berlin, Germany, 2018.

M.H. Brandtner-Hafner, Interface fracture behaviour of industrial adhesives: A novel evaluation approach for adhesive selection, Proceedings of the IN-ADHESIVES Symposium on Innovations in Adhesives and their Applications, Munich, February 14-15 (2017) 221-229.

M. Sakai, R.C. Bradt, Fracture toughness testing of brittle materials, International Materials Reviews, 38(2) (1993), 53-78.

A. Hillerborg, The theoretical basis of a method to determine the fracture energy GF of concrete, Materials and Structures 18 (4) (1985) 291–296. DOI:10.1007/bf02472919

M.H. Brandtner-Hafner, Assessing the natural-healing behavior of adhesively bonded structures under dynamic loading, Engineering Structures 196 (10) (2019) 109303. DOI: 10.1016/j.engstruct.2019.109303.

M.H. Brandtner-Hafner, Structural safety evaluation of adhesive bonds: A fracture analytical approach, Engineering Failure Analysis 123 (5), (2021) 105289, DOI: 10.1016/j.engfailanal.2021.105289.

M.H. Brandtner-Hafner, D. Diáz Batista, Techno-economic evaluation of biocomposites: A fracture analytical approach, Engineering Fracture Mechanics 240 (12) (2020) 107346. DOI: 10.1016/j.engfracmech.2020.107346.

M.H. Brandtner-Hafner, Adhesive bonding systems for construction and building materials, SOVA Materials Science & Technology, 4 (1) (2022) 1-9, ISSN: 2634-5331

M.H. Brandtner-Hafner, Structural safety evaluation of adhesive sealants, Proceedings of the IN-ADHESIVES Symposium on Innovations in Adhesives and their Applications, Munich, May 12-13 (2022) 56-61.