ClarkDietrich, the largest manufacturer of cold-formed steel framing products, interior and exterior finishing products, and accessories in North America announced today that the company has completed its acquisition of Structa Wire Corp, a manufacturer of high-performance welded wire products for the lath and plaster industry.

…Yearly Archives : 2022

The $160 million New Patient Facility at the Hawaii State Hospital is a four-story, 144-bed, 196,944-square-foot secured psychiatric facility on an existing psychiatric hospital campus. At the foot of the Ko’olau Mountain Range, this facility includes patient care units, a rehabilitation mall, multiple office spaces, a standalone central utility plant, a separate gymnasium for recreational therapy, and a site elevator with a walkway bridge structure. Due to the ever-increasing patient population and a high percentage of high-risk forensic patients, the existing hospital could not keep up with the demand, and a larger facility was needed. The project was executed using the design-build delivery method led by Hensel Phelps.

…The old Social Science Building at Weber State University, located in Ogden, Utah, was constructed in 1970. Programmatically, the building has been one of the most heavily used on campus, serving the social sciences, humanities, and many other departments throughout its life. One would be hard-pressed to find a graduate of the University who had not taken a class there. The concrete building, consisting of one floor below grade and three floors above, remained largely unchanged in its 45-year useful life.

…“Come gather ’round people wherever you roam and admit that the waters around you have grown and accept it that soon you’ll be drenched to the bone. If your time to you is worth savin’, then you better start swimmin’, or you’ll sink like a stone for the times they are a-changin’.” – Bob Dylan

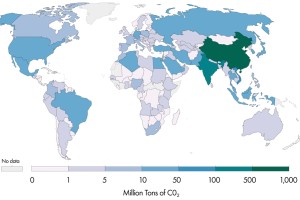

Times in the electric utility world seem to be more rapidly a-changin’ than ever before. Why you may ask, do I mention the electrical utility industry in STRUCTURE magazine? While it is obvious that Electrical Engineers are the beating heart (at 60 Hz) of the electric power grid, Civil and Structural Engineers add the bones and create the muscle that helps give the grid its strength, durability, and, dare I add, resiliency? The challenges facing the electric power grid are unique and unprecedented. As the Bob Dylan refrain elaborates, the waters of change are growing and we… better start swimmin,’ or you’ll sink like a stone!

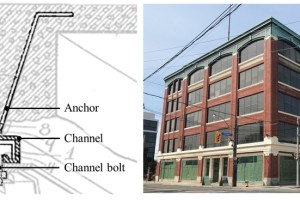

…Anchor Channels in Industrial Structures, Bridges, and Tunnels

Anchor channels with channel bolts enable the robust anchorage of components to reinforced concrete structures. State-of-the-art systems comprised of anchor channels and channel bolts, also commonly known as anchor channels, handle static, seismic, and fatigue loads in any direction. Installing components with channel bolts is fast and easy even under adverse conditions, where wind, water, and confined space entry restrict work activities, particularly with electrical equipment needed for welding, or when overhead installation may be too exhaustive for the installer due to long installation times.

…Per ACI 318-19 and ASCE 7-22

This article provides background on the recognition of ductile coupled shear wall systems of reinforced concrete in ASCE 7-22 Minimum Design Loads and Associated Criteria for Buildings and Other Structures (ASCE 2022) Table 12.2-1, Design Coefficients and Factors for Seismic Force-Resisting Systems. The system itself is defined in ACI 318-19 Building Code Requirements for Structural Concrete (ACI 2019).

…Compliance Beyond the Code

As the most widely used manufactured material on the globe, concrete is one of the materials that may be considered part of society’s foundation. Concrete can be a highly durable, resilient, and affordable material in the built environment, supporting sustainable, economic, and social development when properly proportioned. In addition, concrete can be molded into nearly any shape at the job site, bringing versatility to construction and making concrete a highly popular construction material.

…Myth Versus Reality

Lightweight concrete has been a staple of the built environment for centuries, predating the Roman Empire. While some early lightweight concrete structures still stand, their materials bear little resemblance to today’s offerings. Industry professionals now recognize structural lightweight concrete as a strong, low-density mixture of Portland cement, water, and various combinations of normal weight aggregates and lightweight aggregates. In such concrete, lightweight aggregate produced from shale, clay, or slate is heated to approximately 2000 degrees F in a rotary kiln process. During this process, it softens and bubbles form that remain as unconnected pores when it cools.

…