Red Rocks Amphitheater is considered one of the world’s premier concert venues. Located in Morrison, Colorado, the open-air concept was constructed between a series of sandstone rock formations, creating a natural amphitheater with some of the best acoustics and visuals in the world. When the amphitheater first opened in 1941, the stage was uncovered and exposed to rain and snow, which could arrive at a moment’s notice traveling over Colorado’s Rocky Mountain Front Range. The stage remained uncovered until 1989, when a steel space frame was constructed out of small diameter pipe sections. For 30 years, the original stage roof was functional to shelter performers from the elements. Still, over time, the roof was deemed structurally insufficient due to rigging issues inherent to its design and increased rigging demands as shows became larger from a production standpoint. Therefore, the facility owner and the City and County of Denver asked for the complete removal of the existing roof structure and a replacement structure with an increased rigging capacity, which was safer to use and complemented the surrounding setting.

…Yearly Archives : 2022

Cast iron columns, commonly used in building construction in the 1800s and early 1900s, possess low tensile capacities and require special attention to detail in building alterations. 315 Hudson Street is a ten-story cast iron column building undergoing such alteration in New York City. Extensive renovations to the building included lowering a portion of the ground floor structure, transferring two off-grid columns at the ground floor via transfer beams at the second floor, and reinforcing columns for new rooftop loads. Each endeavor required novel detailing to brace, support, and reinforce the cast iron columns in a manner that limited tension on the cross-section.

…Nestled into a hillside of ponderosa pines with views of Humphrey’s Peak, the High-Performance training facility attracts top student-athletes to Northern Arizona University. DLR Group delivered a 65,000 square-foot, three-story, state-of-the-art High-Performance Center with a 10,000 square-foot weight room, sports medicine spaces, academic center, practice basketball courts, team meeting rooms, locker rooms, and a hall of fame. The facility also has an iconic team auditorium on the third level, with unobstructed views of the 12,600-foot Humphrey’s Peak and the San Francisco Range (Figure 1). The unique spaces and environment provided structural challenges and opportunities for creative design.

…Boston University Center for Computing & Data Sciences

How do you build a 19-story, 305-foot-tall tower with 25-foot cantilever volumes offsetting in a counter-clockwise arrangement every two to three stories around the perimeter? Early discussions with Boston University, the design team of KPMB Architects, structural engineering firms Entuitive and LeMessurier, and construction manager Suffolk Construction identified the means and methods of erection as critical to the success of the Boston University’s Center for Computing & Data Sciences Building. Design-Assist, starting after the submission of Schematic Design, was utilized to identify the temporary erection procedures required to construct the tower. Steel fabricator, Canatal Industries, erector Prime Steel Erecting, and their engineer Simon Design Engineering were engaged to partner in the Design-Assist process with the design team.

…As a new engineer, I was at a site one afternoon struggling over a portion of a project not installed per plan. The contractors’ position was that the plan asked for something that was not done. The design team’s point was that they should have qualified their bid if the contractor knew this was not possible. My role was to defend specifying that the elevator guide rails for a 2-story wood framed building with less than 10-foot story heights needed to span floor-to-floor (i.e., a guide rail support tube would not be provided). While the details were eventually worked out, the outcome of this experience is the more important story.

…Achieving AESS and AESSS Goals

When properly executed, the decision to expose structural steel offers a powerful opportunity to express a project’s tectonics and aesthetic goals. The 2016 American Institute of Steel Construction (AISC) Code of Standard Practice for Steel Bridges and Buildings (ANSI/AISC 303) introduced the architecturally exposed structural steel (AESS) category system, a systematic method of communicating craftsmanship quality to support goals for the final appearance of the finished structure. Prior to 2016, the lack of a categorized approach uniformly accepted by the Architecture-Engineering-Construction industry posed challenges in communication between the design and construction team, as well as with Owners. Today, when properly understood and leveraged, the Category system can support project outcomes that meet designers’ intent, are properly budgeted during the bid process, and achieve ultimate aesthetic goals for which fabrication quality is a foundation.

…An Alternative to Traditional Podium Levels

Developers are always looking for new and innovative ways to make buildings more profitable and financially efficient. Traditionally, a multi-story bearing wall building over one to two levels of steel or concrete, also known as a podium structure, has filled this need by offering high-density residential units at the upper levels and parking or retail spaces at the lowest floors. For multi-story residential buildings, wood construction is generally considered the most cost-efficient form of construction, followed by cold-formed steel (CFS) bearing walls and then heavy steel or concrete framing. Because of this, developers have sought to maximize the number of wood-framed floors over the podium level before switching to more costly materials.

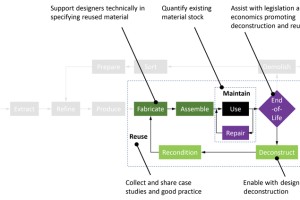

…Implementing Circular Economy Principles in Structural Engineering Practice

Last year, the Intergovernmental Panel on Climate Change (IPCC) stated: “It is unequivocal that human influence has warmed the atmosphere, ocean, and land… Observed warming is driven by emissions from human activities. The scale of recent changes across the climate system as a whole are unprecedented over many centuries to many thousands of years.” Of course, these emissions are a product of global society as a whole. However, the building construction industry has been a significant emissions contributor and material user; approximately 40% of global material extraction is for housing, construction, and infrastructure. As structural engineers, we have a fantastic opportunity to be impactful leaders in reducing material use and emissions.

…Temporary and permanent shoring is often a necessary factor when designing/constructing new building structures in urban areas. The National Council of Structural Engineers Associations’ (NCSEA) Excavation Shoring Design Guide was created and published to aid structural engineers by providing a single source document. The Guide incorporates all the available codes from the federal government and state agencies so engineers can adequately guide the design team and owners to have the most economical project.

…System Description

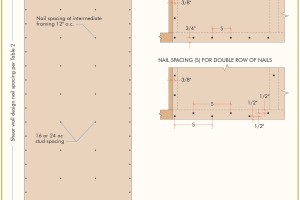

Using wood structural panels that are required to resist lateral loads and normal wind load requirements of the IBC Section 1609.6.4.4.1, Chapter 30 of ASCE-7, or IRC Section R301.2.1, additional wind uplift resistance from the panel can be achieved by providing additional nails to the shear nailing at the top and bottom of the panel. These additional nails are used to transfer the uplift forces from the top plate to the panel, from panel to panel at splice locations (if present), and from panel to sill plate at the foundation, effectively eliminating the need for uplift straps at these locations. Uplift straps may still be required around window and door openings in exterior walls to transfer the wind uplift loads acting on the header to the foundation below.

…