Home to less than 2,000 residents, the quaint Village of Cambridge, NY, lies between the foothills of the Adirondack Mountains of upstate New York and the Green Mountains of Vermont. About 150 years ago, Cambridge was home to the Jerome B. Rice Seed Company, the second-largest seed company in America at that time, with clients throughout New England and the Eastern Seaboard.

…Yearly Archives : 2022

The (Stephen) Long Covered Bridge, from Brownsville to Columbus (Indiana)

The year is 1840, and the townsfolk of Brownsville, Indiana, were dismayed that the newly constructed National Road was crossing the East Fork of the Whitewater River, just a few miles north of town. They engaged Stephen Long to construct a bridge for the town, and his patented Long Truss soon spanned the river… The year is 1993, and the same bridge now lies in Columbus, Indiana – with many miles in between at the end of an interesting journey.

…“The time has come for all good men to come to the aid of their country.”

This famous quote resides somewhere in my brain, and as I start my tenure as NCSEA President, it recently resurfaced. Not that it is applicable word for word. And in the current geopolitical environment, this phrase has much more serious connotations. But maybe substitute “profession” or “environment” for “country” and exchange “people” for “men.” With those edits, this phrase seems to suit my mindset well.

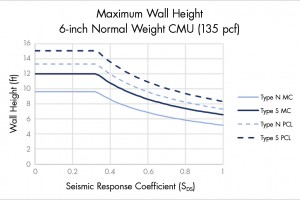

…In terms of structural concrete masonry unit (CMU) construction, the predominant unit sizes are nominally 8-inch and 12-inch-wide units. However, with rising material costs, 6-inch-wide units are ideal for interior and exterior wall construction depending on wall heights and design loads.

…The use of masonry began with unreinforced dry-stack (mortarless) construction. For millennia, stone has been laid dry without mortar. The Great Pyramid of Giza (c. 2600 BC) is an example of limestone and granite ground smooth and fits tight without mortar (Figure 1). There are numerous examples of residences, walls, fortresses, and towers constructed using dry-stack masonry throughout the world. Unreinforced, these structures rely on gravity and friction to maintain their stability.

…Today, price and strength may not be a decisive selection criteria and super-strong adhesives are not a gamechanger for concrete bonding.

…How Much is Enough?

Structural engineers often get a greater level of comfort by specifying masonry component strengths higher than are needed. However, this can be counterproductive since some masonry components, such as mortar, may sacrifice bond in lieu of strength, leading to cracking and water intrusion into structural masonry walls. Masonry grout may also be considered a form of concrete, which it is not. A better approach is understanding how the individual materials work together based on code requirements supported by extensive research. The ultimate goal should be to specify masonry components that are economical with maximum structural integrity.

…The phrase “the devil is in the details” applies to anchor bolt design in masonry structures. The anchorage of masonry members is essential both for load transfer into the member and for stability and support of the member. There are typically two types of anchors used in masonry. Cast-in-place anchors, or anchor bolts, are generally designed using TMS 402 Building Code Requirements for Masonry Structures. Post-installed anchors are generally designed based on manufacturers’ data, with the design capacities of the anchors determined through International Code Council (ICC) Evaluation Service reports. This article focuses on anchor bolt design and, particularly, several recent revisions in the 2016 version of TMS 402 that will help with the design of anchor bolts.

…To Top Rail or not to Top Rail

The engineering of guardrails has generally been straightforward ever since they were first addressed in building codes. Even the earliest building codes, like the Uniform Building Code (UBC) and the Building Officials and Code Administrators’ (BOCA) National Building Code, had live load requirements for typical handrail and guardrail scenarios.

…Part 2: Significant Changes to Design and Detailing Requirements

Significant changes were made to the design and detailing requirements for special steel-reinforced concrete structural walls in the 2019 edition of Building Code Requirements for Structural Concrete (ACI 318-19) (hereafter referred to as ACI 318).

…