Batch hot-dip galvanizing (HDG) after fabrication, a total immersion process in molten zinc, has a more than a 150-year track record of providing corrosion protection for steel in the harshest environments. Though primarily known for corrosion resistance, hot-dip galvanizing following ASTM A123, Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products, is increasingly specified for low initial cost, durability, longevity, availability, versatility, sustainability, and aesthetics. To achieve these additional benefits, there are several areas where structural engineers and detailers can work together to ensure steel pieces are successfully fabricated to achieve maximum galvanizing quality without negatively impacting structural integrity. The best practices specific to hot-dip galvanized steel may be unfamiliar to structural engineers and detailers experienced in other methods of corrosion protection, but an upfront effort to incorporate these details will pay dividends in terms of reduced cost, quick turnaround, and optimal quality. This article summarizes key topics which have the most significant impact on the quality of hot-dip galvanizing for general corrosion protection, Architecturally Exposed Structural Steel (AESS), painting or powder coating after hot-dip galvanizing, and fireproofing. …

Review Category : Articles

The Northridge earthquake struck the greater Los Angeles area during the early morning hours of January 17, 1994. The earthquake was responsible for approximately 60 deaths, more than 9,000 injuries, and an estimated $20 billion in damages. Significant ground shaking occurred over a wide area and exceeded design code values in many locations. Numerically, most of the damage was to wood-frame residences, but upwards of 200 concrete buildings were red-tagged. The Northridge earthquake was the first big test of pre-1980 concrete buildings and post-1980 buildings designed using updated code provisions following the 1971 San Fernando earthquake. …

Raising the Bar for Testing and Quality Assurance

It is a familiar situation for anyone who has been involved in a masonry construction project. Things have progressed through design, bidding, and contracting, and are in the construction phase. One day, as part of the specified quality assurance program, a testing laboratory technician visits the job, samples materials, and takes them away for testing. Sometime later, usually after 28 days, the dreaded call is made – the materials are not compliant. The project shuts down, meetings ensue, and further evaluation, usually costly destructive testing, is performed. Finally, additional testing shows satisfactory results and the project resumes. However, this process has caused significant lost time and testing. …

Resilience may be the phrase of the decade, but it is not a new concept. Structural engineers have been building resilience all along; it is only now that others are catching on. And, as structural engineers, there are tangible steps we can take to amplify the resilience we build.

Consider the broader meaning of resilience: the ability of a person or system to adapt to shock and return to a “new normal.” …

Part 1: History of the Philadelphia Demolition Ordinance and the Apex Hosiery Building

This four-part series discusses how the collapse of a building during a demolition operation in Philadelphia in 2013, which resulted in several fatalities, led to enactment of a City Ordinance to prevent similar future calamities. As a result of the Ordinance, the author became involved with the structural investigation, review of the Site Safety Demolition Plan, and Demolition Special Inspections associated with the adaptive reuse of the Apex Hosiery Company Building located in Philadelphia. …

Affordable Housing Explained

Affordable housing is in the news more than ever before. As rising rents and harrowing rates of homelessness echo across the country, housing advocates are relieved to see the spotlight finally shine on the need for this essential community resource, but their relief is shortlived. All this attention is the result of millions of families searching for a stable place to call home. The National Low Income Housing Coalition (NLIHC) estimates that there’s a shortage of 7.2 million homes. Innovative partnerships are slowly creating positive change. To build more and better housing for the people that need it most, resourceful engineers are necessary. Affordable housing building trends offer a glimpse into the sweeping social change affecting neighborhoods and how engineers can make a difference. …

Our firm is fortunate to be celebrating our 50th anniversary this year. We have grown from a one-person firm to a dedicated staff of over 30. That growth has not been exponential, but it has been steady and consistent. Recently, while preparing a presentation for our employees about our 50-year history, I had the chance to reminisce about some of the successes and challenges since 1969. I have been around for 36 of those 50 years, so I have some knowledge of our history, but I was reminded of some of the work our firm did in those earlier years. The founder of our firm still visits with us occasionally and attends company social functions, so we still have a connection to our founding, and it is great to have that connection. …

A Basic Primer

Fiber-reinforced polymer (FRP) composites are engineered to resist corrosion and provide high strength-to-weight and modulus-to-weight ratios compared to steel and concrete. In simplest terms, a composite material is produced when two or more substances are combined to take advantage of their unique strengths while overcoming their weaknesses. The first use of composite materials can be traced back to 1500 B.C. where Egyptians and Mesopotamians mixed mud and straw to create strong buildings. In the 1900s, the development of plastics birthed synthetic resins. Owens Corning introduced the first glass fiber combined with polymer resins. Following WWII, composites made their way into cars, airplanes, and boats, among other things. …

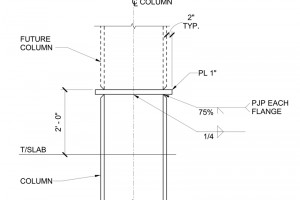

How many times have you designed an addition to an existing building and wondered, “What was the engineer thinking?” Many types of structures are designed for future expansion in anticipation of the ever-changing needs of the owner and community. Hospitals are frequently designed for additional floors. Structural engineers play an essential role in designing and detailing the structure to accommodate future expansion, as well as helping the owner and design team plan ahead for the intended use and functionality of the additional floors. …

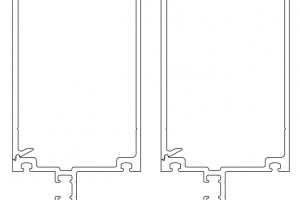

Curtain walls use extruded aluminum mullions to support glass lites, which are subjected to wind pressures acting inward and outward on the building exterior (Figure 1). The primary loading on mullions is flexure, but determining their flexural strength is complicated by several factors: …