Transportation tunnel design and construction requires accepting the inherent uncertainty associated with subsurface conditions that can be characterized but never truly known. This article follows the geotechnical arc of a typical tunnel project from explorations and testing, to engineering analysis, supporting the selection of tunnel excavation methods, characterizing ground behavior, developing parameters for liner design, and estimating surface settlements and effects on adjacent structures. It provides examples from completed projects to highlight the risk and mitigation methods associated with underground construction. …

Review Category : Articles

Urban areas are becoming more densely built: consequently, surface space is less available. The United Nations recently projected that 68% of the world’s population would live in urban areas by 2050 (up from 55% at present). Thus, it is expected that cities, counties, and states will increasingly look to underground structures as alternatives to surface infrastructure to address space constraints. The increase in the number and extent of tunneling projects also increases the complexity of urban infrastructure development, necessitating structural and geotechnical or tunneling engineers to collaborate closely to deliver an efficient and practical design while managing impacts on existing structures. …

Squire Whipple built two wooden swing bridges in Ontario, Canada, in 1853 on the Great Western Railway. One was near Hamilton, Ontario, at Dundas and the other over the Welland Canal at Thorold Station just west of Niagara Falls. The bridge at Hamilton, called the Desjardins Bridge, opened in early November 1853. The turntable was on the bank and not in the center of the bridge as was generally the case. Large masonry abutments had been built to cut down the length of the swing span required. In addition, a wooden structure was built, upon which the swing span rested when it was in an open position. The waterway was 66 feet wide and required a swing span of eighty feet (from the center of turntable to the far abutment) to reach the other side of the channel. …

Part 2: Seismic and Wind Drift

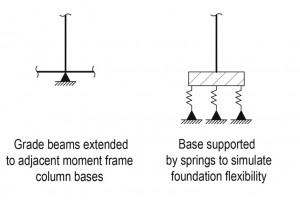

This article is the second of a two-part article on ASCE 7-16, Minimum Design Loads for Buildings and Other Structures, and its provisions for lateral drift determination. The first article (STRUCTURE, July 2019) discussed main points influencing seismic drift computation. In this article, the effect of soil flexibility and cracking of reinforced concrete elements on seismic drift computation of structural systems is addressed. It also discusses the determination of the level of loads for checking wind drift, return periods of wind speed maps, and allowable wind drift limits. A brief comparison between seismic drift and wind drift, in connection to their nature, and a determination procedure is covered. …

There is no shortage of articles that make claims about how our work can and will be automated in the future. With the recent surge of development happening on the topic of Machine Learning, these claims continue to grow. The reality is, our industry is in a constant state of evolution. …

Many times, the phrases quality assurance and quality control are used interchangeably. Quality assurance (QA) is process-focused, where the processes are put in place to ensure the correct steps are performed. Quality control (QC) is used to verify that deliverables are of acceptable quality and that they are complete and correct. As this relates to structural engineering, one may think of QA as the process we go through during our design and construction document production phases and QC as the review exercise at the end of a project to determine how well the process worked in producing a quality set of construction documents that met the needs of the client, owner, and contractor. …

Let’s face facts. It is unlikely that the majority of practicing structural engineers are familiar with the material contained within the International Residential Code (IRC). …

Multi-Unit Residential Construction

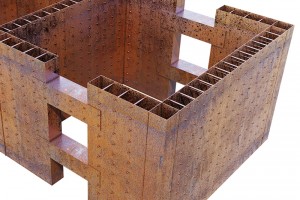

Pre-fabricated, structural cold-formed metal framing (CFMF) bearing walls are a trending construction system and an economical alternative to structural steel or reinforced concrete systems for mid-rise construction. CFMF wall systems are particularly desirable for 6- to 12-story multi-family apartments or condominiums, student housing, senior living, and hotels. Vertically-aligned residential demising and partition walls allow the CFMF to stack like timber-framed or concrete masonry unit (CMU) bearing wall construction. However, CFMF wall buildings are less height restrictive than timber due to steel’s higher strength and not as labor-intensive as CMU because of pre-fabrication. Additionally, CFMF systems integrate wall panels as the structural system in what would typically be non-structural, stick-built partition walls. …

Lateral System Innovation for Today’s Construction Challenges

The millennial mindset is saving our profession. A common question from young engineers – “Why do we do things the way we do them?” – can be just as off-putting to us as it is to the Baby Boomer down the hall. The more experienced engineers often side with Gen-Xer points of view and the played-out stories of rotary phones, record players, and the lost art of hand-drafting. All we want to say is: “because we do.” …

Specifying an Effective Quality Assurance Program

The quest for quality construction following a professional design by the Structural Engineer is not a new concept. The initial publishing of the 1927 Uniform Building Code (UBC), subtitled the material disciplines “Quality and Design,” acknowledged the relationship between the design and implementation of a construction project. Over the past 90 years, Quality Assurance, the development of a program, and Quality Control, the implementation of that program, have evolved in such a manner that details can often cloud the ultimate intent. …